use GROVE cables for the sensors one comes with every sensor. The MBus interface at the bottom of the core2 is not intended to connect by Dupont lines. If you want to tinker additional hardware to M-Bus then one of the PROTO module might be useful. It adapts the Bus to 2.54mm (0.1") spaced solder points. You are free to use Dupont from there.

Best posts made by holofloh

-

RE: What is the best Dupont cable size to use with ESP32 Core and Core 2 controllers?posted in General

-

RE: Limit to 2 Decimals in labels in UIFLOWposted in SOFTWARE

in the section "Text" is a piece that calls "Reduce ... to ... decimal places"

-

RE: m5go World Clock Problemposted in M5GO

Hi,

your question reads like "my car will not start, what shall I do?". The standard answer to that question is "buy a new car" even if the solution would be as easy as "turn the key" or "fill some gasoline".

From your description we know you want to have a world clock and you have a m5go. What is missing:- The environment you use to code your clock

- Your code which seems to be the problem

- the exact error message or a picture of what you call "overloaded"

please read this post first: https://forum.m5stack.com/topic/535/forum-rules-read-this-first-before-posting

-

RE: Smart Applications of Holography and Robotic Arms myCobot 320 M5Stack-Basicposted in PROJECTS

Just my comment about the missuse of the words "hologram" and "holography":

Displaying a stereoscopic or augmented reality image that seems to be floating in the room has nothing to do with holograms or holography. It is impressive YES, but it is NOT a hologram. Why do I know this? Look at my nickname! I have made my own REAL optical holograms for many years. They are made by interfering high-coherent wavefronts coming for a laser source and recording the resulting pattern in a 2D surface. There are different types of setup but all have in common the interference of a reference-beam with a object-beam. See https://en.wikipedia.org/wiki/HolographyHowever, mounting a real hologram on a robot arm and move it around is also possible. In case of a hologram that changes its displayed content by the angle of the light source it can be very impressive!

-

RE: Webserver with UIFlow?posted in UIFlow

EZData is just one of the possible data storages. With M5 products it is very easy to use. It is also possibe to use other cloud services. Cloud means "some storage somewhere on the internet". It requires a connection to the internet anyway.

Some ideas:

- Use a separate non interupted connection such as LoRa or mobile internet for your battery measurement. Depends on what is possible at your location and what/how you need to communicate.

- log to a cloud like storage in the local network, powered by battery on mains loss. No access during power loss but all data saved

- Detect the internet connection loss and log to SD card until the connection is back, then upload all missing.

-

RE: Atom Lite not connecting as local Access Point on WiFiposted in Atom

If you compile the example WiFiAccessPoint then it means the Atom turns into a WiFiAccessPoint. If you entering the same SSID and PW as your home Wifi then it means you are creating an additional access point on the Atom with the same name as the existing one. This may be confusing. The IP Address of 192.168.4.1 is the local address of the Atom now. Change the SSID on the Atom to something else to avoid the confusing.

To connect your Atom to the existing wifi you need a WifiClient sketch or any firmware like UIFlow that has one included. After connection to your home Wifi the Atom gets an IP Adress from your home DHCP Server which is running on the Wifi Router in most cases. This should be one in the 10.0.0.xxx range if this is your home network. -

RE: DMX Addressingposted in Modules

I don't see your problem. Just send the data to the according address of your light.

Maybe you do not understand the addressing of DMX lights?

You need to configure an individual start channel (address) for every light with a spacing of at least the number of channels your light support. E.g. your RBGW light is set to 4-channel-mode and its start channel is set to 1, then it listen to the channel 1, 2, 3 and 4. The next light can have the start channel 5 and so on. Some more complex lights like moving heads can have more than 30 channels. It is possible to have up to 512 channels per physical bus (called DMX universe)

You may set several identical lights to the same address but then they all do the same.

Also very important: The last light in the bus should have a terminator plug/resistor. It may work without but often a missing terminator cause strange effects on the DMX bus. -

RE: Hall effect Unit SKU:U084 programmingposted in PRODUCTS

Here you find the information about this module: https://docs.m5stack.com/en/unit/hall

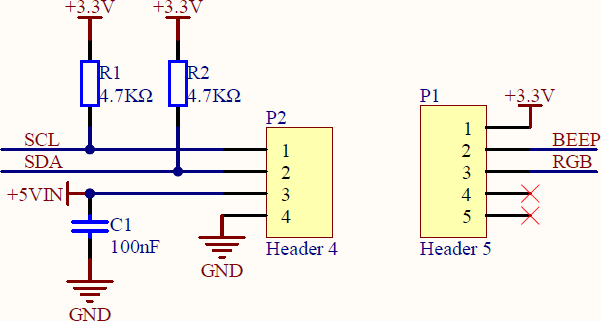

According to the schematic it contains three A3144 Hall-sensors and a 74HC08 AND-Logic.

The datasheet of the A3144 tells me that it has an open-collector output and the schematic that they are pulled up to 3.3V by resistors.

So the function is: as long as all three sensors are not in a magnetic field that is higher than the level for switching (see datasheet), the AND gate output is HIGH. If one or more of the sensors are triggered by magnetic field, the output goes LOW.

There is nothing to configure or program inside the module. The decission if the module fits to your project is up to you. By the way, if you plan to use a Arduino compatible controller it might be an option to use one that is based on ESP32. The controller already contains a Hall-Sensor.Just that you know: M5Stack does not make a mystery about the inside of their modules. You always find a schematic and all the datasheets that tells you everything about the hardware and its function. It is a big benefit if you learn to read and understand this informattion.

-

RE: Read PWM Signal from Deviceposted in Atom

there are 2 variants:

A) the PWM signal can be captured by measuring the time ratio between 1 and 0:

- Put the PWM signal into one of the GPIO. Make sure the voltage is not too high, use a voltage divider and if possible a additional Z-diode for protection).

- Set the input to an interrupt source for both edges

- in the INT-routine put the current time stamp into a variable and wait for an oposite edge appears. If you do this in a clever way, the controller can do other things in the mean while (e.g.sending the value over ESPnow)

- once you have a high and a low time you can calculate the ratio.

B) integrate the PWM and measure the analog voltage

- use a R-C circuit to integrate the PWM into a analog voltage

- divide the voltage by a trimmer potentiometer so that 100% equals full scale of the analog input. If possible use a Z-diode to protect the input

- measure the analog value by M5Atom

-

RE: Alte Software auf neuem V1.1 läuft nicht.posted in Deutsches Forum

Deine Frage hilft leider nur wenig bei der Fehlersuche.

- Gibt es Fehlermeldungen, Fehlfunktionen oder wie kommst du darauf, dass das Programm nicht mehr funktioniert?

- Hast du den Quellcode zur Verfügung oder ist der mit dem Programmierer zusammen verschollen?

- Welche Art Programm ist es? Ein UIFlow bzw. Python Script oder eine kompilierte Software in C (z.B. über die Arduino Umgebung)

Ein Script könnte auch von der UIFlow Version abhängen, ältere Scrips laufen nicht immer mit der neuesten Firmware und umgekehrt.

Versuche herauszufinden was zwischen den Versionen der Hardware geändert wurde (z.B. Zuweisung von Ports, I2C Adressen von verwendeten Komponenten usw.). Damit kann man dann den Grund für das Verhalten erklären und nach möglichen Lösungen suchen.

-

RE: [Product Revision] Color Sensor (U009) - Ability to turn off LEDsposted in Features Wish List

According to the schematic the LEDs are hard connected between VCC and GND (with a 1k Resistor in serie). It may be an option to misuse the sensors INT pin and its limit threshold settings to switch the LEDs on and off. It is a open-drain with a max of 20mA. Or spend an extra I2C output driver (one Output for white LED or more if you want different LED colors - deep blue or ultra violet may be helpful to identify e.g. fluorescence).

Anyway, it will never be a spectrometer like device as there are only 3 colored sensors with a more or less wide spectral bandwith but still gaps between. -

RE: How can I download my old script from a device?posted in UIFlow

You can use the "Device File Manager" in UiFlow.

-

RE: Read PWM Signal from Deviceposted in Atom

100 and 27 Ohm? In this Case you burn 118mA @ 15V or 1.77 Watts in the resistors. They may become a bit hot. Could be better with higher restistance (1k + 270 or 10k + 2k7) as the wasted power is smaller but the divider ratio is still the same.

- A Capacitor helps to stabilise the voltage on the input. You can also take a few samples / measurements and integrate it in a software loop to get more acurate value.

- A Zener Diode of 3.3V helps to protect your input. This is very recommended!

I put a small simulation where you can play around: https://tinyurl.com/2lshs6fj

(use the slider on right to change the PWM duty) -

RE: Add MCP9600 I2C Thermocouple Amplifier - K, J, T, N, S, E, B and R Type Tposted in Features Wish List

@mgrouch KMeter is just the thermocouple converter. The TC insulation itself can be made from plastic or silicon or it can be made from glass fabric. It can also be inside a stainless steel housing or whatever. It depends on the application.

I just did a quick search for exhaust thermosensors and there are many K-type thermocouple in different housing available. As long as they have a TC connector or open wires for mounting one by yourself you can use them with KMeter.I strongly recommend you to read the basics about thermocouples and how they work. You may than understand, that this "plastic thing" can be and should be far away from the high temperature exhaust.

By the way: If you feel better with the MCP9600 then buy one from e.g. Adafruit and use it with its library in the Arduino environment. You controller can still be M5. As for the KMeter the MCP9600 breakout is not made to put in the exhaust as well.

-

RE: Centre a label on M5Stackposted in UIFlow

I assume you have changing text in the label. For the Y-axis set the label manually to the half of screen height minus the half of label height. The X-axis can be calculated by using half of screen width and half of label width

label0.get_width(). -

RE: How do I mount all this to a panel in presentable aesthetically pleasant way?posted in Atom

@mgrouch

Some suggestions:- Hot glue

- Scotch Tape

- Brick/Lego tiles

- wooden panel with carved indentation

- 3D-printed brackets like https://www.thingiverse.com/thing:5419887

-

RE: M5Stick-C display shows the words "Not Found."posted in SOFTWARE

try the following:

- set the stick to power OFF

- plug in USB (it will automatically power ON)

- look in M5Burner (or in your computers device manager) if the serial port appears. If not there is a driver issue on your computer or your USB cable might have broken wires (once happened to me)

- if the port appears burn the factory test or UiFlow

I suppose there no need to put the stick in any special mode to burn the firmware. the internal USB chip will do that for you while the programm downloads. Once the UiFlow Firmware is running you have to set the mode for wifi or usb if not already done while burning firmware.

-

RE: RGB Leds Crossfadeposted in UIFlow

This is not an Uiflow specific solution. Try as following:

- Decide how many steps you want from start color to end color. e.g. 10 steps

- find the step size from start to end color e.g. you want from value 100 to 200 (difference / steps) = step size 10.

- loop for the number of steps and increase/decrease the value with the calculated step size.