This looks good, but it doesn't seem to be fully automated at the moment.The running file that controls mycobot needs to be run again.

Posts made by kehu

-

RE: Building a Smart Navigation System using myCobot M5Stack-Base and myAGVposted in PROJECTS

-

RE: The Ultimate Robotics Comparison: A Deep Dive into the Upgraded Robot AI Kit 2023posted in PROJECTS

It looks great! How can I use it?

-

RE: Exploring the Advantages and Differences of Different Types of Robotic Arms in AI Kitposted in PROJECTS

You are right!Choosing a suitable robotic arm is the most important thing.

-

RE: myCobot 280-Ard conveyor control in an industrial simulationposted in PROJECTS

The purpose of the mycobot in this project is just to press switches is it?

-

RE: A four-axis robotic arm ideal for industrial education |myPalletizer M5Stack-esp32posted in PROJECTS

This looks good but the picture seems to look wrong.

-

RE: myCobot VS mechArm | Find your preferred desktop 6-axis robotic armposted in General

mycobot looks very flexible, but you say mechArm is more stable and smooth than mycobot how to reflect it?

-

RE: Desktop Dual-arm Cobot, myBuddy 280 Focuses on Education and Research with Various Functionsposted in PROJECTS

It looks great.I see you guys say it allows for VR linkage is this possible?

-

RE: myAGV | SLAM-based autonomous localization and navigation for robotsposted in General

Can myAGV be equipped with an m5stack, which is used for one-key settings. For example, press one button to open the SLAM algorithm, and then press another button to open the keyboard control? Written as a one-click type.

-

RE: First experience with myCobot280-M5Stackposted in General

Can I develop the M5Stack basic module by myself? In the case of keeping mycobot connected to the computer.

-

First experience with myCobot280-M5Stackposted in General

myCobot is a 6-DOF robotic arm from Elephant Robotics, which owns the highest cost-performance in collaborative robotic arms. This article is about the experience of using the myCobot280-M5Stack. I will program it in python, including environment building, code testing, and, development.

Introduction

Just as its name implies, this robot uses the M5Stack controller. So when using it, we need to build the compiled environment with a computer, and I will be using the python language to do this.

There is an official library named pymycobot, I will use it in python to manipulate the robotic arm.Environment building

Install the python environment on the computer and download the pymycobot library. Two methods are provided:

- A more detailed tutorial on building the python environment is available on Elephant Robotics Gitbook.

- Search the related tutorials on Google.

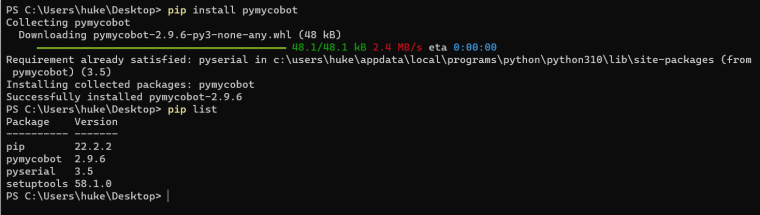

After installing the programming environment, we download the driver library.

pip install pymycobot

Controlling the robotic arm

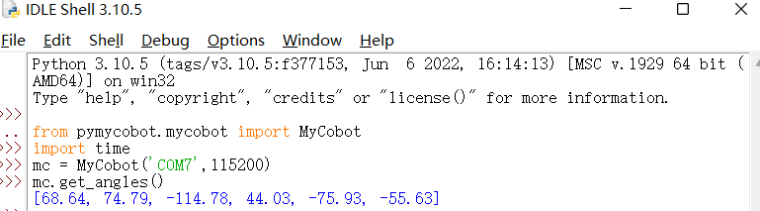

Get started with importing some python libraries.

from pymycobot.mycobot import MyCobot import time(1)MyCobot(port,baud)

To create an object to communicate with the myCobot.

Port: Serial port of the robotic arm.

Baud: Baud rate for the robotic arm.#The serial port of my arm is COM7, baud rate 115200. mc = MyCobot('COM7',115200)(2)get_angles()

To get the angle data of all joints of myCobot.

Return Value: The return value is a list with six elements of data, corresponding to joints 1 to 6.

We can see the angles of myCobot as shown

(3)send_angles(degree,speed)

To send the angle and speed of movement to all joints.

Degree: The angles of the joints are in the range of -180 to 180 and are stored in a list in the order of 1 to 6 joints respectively.

Speed: The speed of the robotic arm during its movement to the specified angle.

mc.send_angles([0,0,0,0,0,0],50)

Run like this.

demo

Forum can't put gif(4)send_angle(id,degree,speed)

To send the angle and speed to a single joint.

Id: Integers in the range 1 to 6. It corresponds to robotic arms with 1-6 axes, respectively.

Degree: The angles of the joints are in the range of -180 to 180 and are stored in a list in the order of 1 to 6 joints respectively.

Speed: The speed of the robotic arm during its movement to the specified angle.

Make a joint's movement reach a position of 90 degrees at a speed of 50.

mc.send_angle(1,90,50)(5)release_all_servos()

To unlock the robotic arm so it can swing manually at will. Note that when this command is executed, the arm will fall due to gravity, so be careful to prevent it from hitting other things.

mc.release_all_servos()

The robotic arm is powered on when it is controlled, and with this function, we can swing the robotic arm.

demo2

Forum can't put gifDemo

Write a demo to make myCobot280-M5Stack dance.

#!/usr/bin/python3 #-*- coding: UTF-8 -*- from pymycobot.mycobot import MyCobot import time mc = MyCobot('COM7',115200) mc.send_angles([0,0,0,0,0,0],50) time.sleep(1) for count in range(3): mc.send_angles([87.8,(-51.5),60.9,11.95,(-15.9),(-6.06)],50) time.sleep(1) mc.send_angles([87.97,42.01,(-45.26),10.37,(-15.9),(-6.06)],50) time.sleep(1) mc.send_angles([19.77,79.36,(-114.34),39.63,(-15.9),(-6.06)],50) time.sleep(1) for count2 in range(4): mc.send_angles([43.24,93.42,(-140.88),48.07,60.64,(-6.06)],50) time.sleep(1) mc.send_angles([19.77,79.36,(-114.34),39.63,(-15.9),(-6.06)],50) time.sleep(1)demo3

This is the end of myCobot280-M5Stack first experience.

If you like this article, please give me a like or leave a comment to support it. Thank you! -

RE: The highest cost-performance mobile robotic platform for individual developers.posted in General

Looks very nice. A couple of questions:

-

Your website says that the payload is 2000g – is that a typo? 2kg payload is not a lot and the arm that you show mounted on it looks like it might weigh a lot more than that.

-

Omni-directional wheels have notoriously poor odometry. Does the robot have an IMU that is used to compensate for that for localization?

-

-

RE: How to solve the problem of RVIZ freezing?posted in General

Please check that you are using gpu acceleration and not just software rendering. This can be seen in the output of rviz at startup for example